ICAM V25.0 Release

These release notes describe the most significant V25.0 enhancements and problem corrections.

We hope you enjoy your new release of the ICAM products and we sincerely welcome your feedback.

The CGTech ICAM R&D Team June 15, 2024

Systems and Packaging

Product Availability

System Manufacturer |

O/S Minimum Requirement |

Microsoft Windows 64-bit |

10, 11, 2016, 2019, 2022 |

ICAM software is not available for UNIX systems. An ICAM database created with V20 or earlier on a UNIX system is fully compatible with ICAM software running on Windows systems.

ICAM V25.0 can run under Microsoft Windows 7, 8 and 8.1, and Microsoft Windows Server 2008R2, 2012 and 2012R2, but these operating systems are no longer supported by Microsoft.

** V25.x do not support 32-bit architectures. The 32-bit installers are available with V24.x on demand only. Contact support@icam.com should you require a 32-bit installation. Note that using 32-bit is a disadvantage, having less available memory for a running process.

Productivity Tools

Quest Developer’s

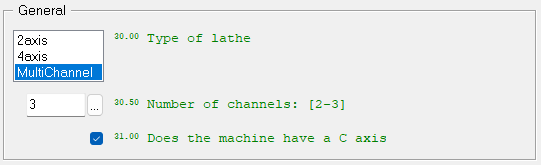

Mill-Turn support for 3-channel Mill-Turn machines. CAM-POST was supporting dual channels processing by using the XYZ axes for defining linear axes for the main channel and UVW axes for the side channel. That design was changed to be extensible to more than two channels. The following enhancements have been introduced to support the third channel:

New registers for linear axes controlled by channel 2 and channel 3 can be specified easily in the Linear axes section.

The User defined macro section LOAD feature can now optionally insert macros in the existing set from an external macro file. When browsing for the macro file, a check-box can be toggled to insert instead of overwriting.

We added new macro function and variable to enable macro usage on generated positioning move. A new macro function $FOPPATH((id|AUTO)[,type]) and new system variable $OPPATHI allows to retrieve and examine individual motions generated by Path Planning, by RTA or by SmartPATH optimization. That, in turn, will make the process of decorating the motions easier.

New CL record light look-ahead can gather information from the CL data with minimum processing.

While $FLOOK() and $FINFO() are full processing look-ahead, the $FCLINFO() macro function is aiming at quickly scan the CL file records and retrieve some key information describing organization of the manufacturing process. Please note that the scan still provides some basic level of macro processing.

The Control Description / High Speed Machining section has been enhanced with new questions to better estimate RAPID positioning time. Different types of positioning are taken into account. This includes cases when all axes move independently, when motion of rotary axes is slaved to motion of linear axes and when all axes are moving and interpolating together (typically RTCP positioning motions).

New question #200.40 determine if the post-processor should simulate RAPID positioning motion and take into account time to accelerate and decelerate.

#230.60 is used to define the units for rotary axes acceleration. Degrees or radians.

#261.00 define if RAPID motion decelerates at the end of each motion or path. Some controls will maintain the velocity throughout the full extent of RAPID interpolated (TCP) path while other may decelerate or stop at the end of each motion.

#262.00 specifies the percentage of RAPID deceleration When the machine decelerates at the end of the RAPID motion, the axes may come to the full stop or, the velocity is just reduced by certain amount.

#263.00 define if there is a wait time applied at the end of a RAPID motion. Some controls will wait at the end of RAPID motion to make sure the tool is well in position.

Gener Post-processing

Enhancement for 3-channel Mill-Turn. Post-processor vocabulary is also enhanced to control the processing for each channel. The “CHANNEL” command has been added to specify the channel number to which the commands are intended and to specify where simultaneous processing commands are started and ended. Moreover, the “SYNCTR” command is also introduced for indicating location of synchronization points between different parts of the program. The new syntaxes of the commands are the following:

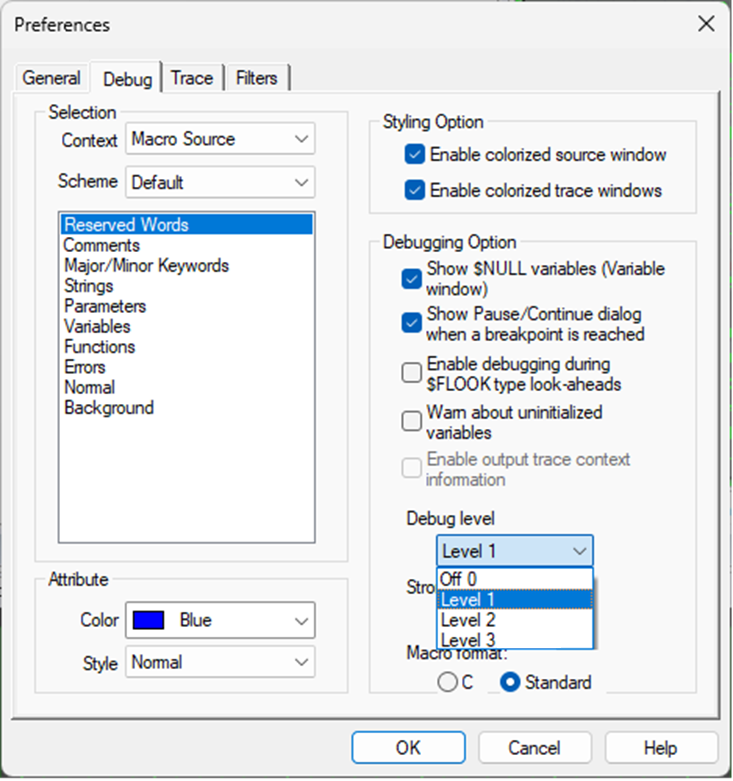

The existing preference “Enable debugging during $FLOOK type look-ahead” will now show diagnostics generated during the look-ahead. By default, when any look-ahead of $FLOOK() type is running the execution, the process is the same as in normal process mode but no tape output, no listing file and no diagnostics are generated. In case when something goes wrong the user is not aware of the situation. In this release we have provided an option for all diagnostic to be output during $FLOOK() look-ahead. This way, in addition to the existing $DIAGLIST, the user will have visual indication of any encountered issue.

The new ROTABL/SINGLR[,(ON|OFF|NEXT][,sing_pos] command allows to specify preferred orientation of a rotary a singular positioning motion. When no other conditions exist (for example, special position was not requested by Path Planning or by Polar optimization), then the user preferred singular position will be respected.

- Improvement to the interaction between SmartPATH and SmartCUT. These two optimization features are closely cooperating with each other. SmartCUT feature designates which cutting motion can be converted to positioning motions. Then, SmartPATH optimization replaces those converted motions with new, optimal and safe passage.We added a new command SMART/AIRCUT,AP,(ON|OFF) to instruct the post processor if air cutting motions should be left alone, as they were programmed or, if these motions should be replaced by SmartPATH for optimal motions.

Enhancement to Travel Optimization for Singular tool path. Singular motions optimization can be applied to the motions when tool axis direction is parallel to the rotary table rotation axis direction. The use of LIMIT/POLAR command CAM-POST can generate over-travel free path. For example, CYCLE operations were not covered by proactive optimization. Current software release implements enhancement for singular optimization. CAM-POST is now able to apply proactive singular optimization to a series of CYCLE points. The positioning motions moving the tool between any two holes can be still exposed to the SmartPATH optimization if SmartPATH is also used.

LIMIT/POLAR,…,SCAN,ON

New MCHTOL/CONTUR,RAPID command to control the new high speed machining RAPID time estimation as described in the Questionnaire section above.

Gener & Cerun

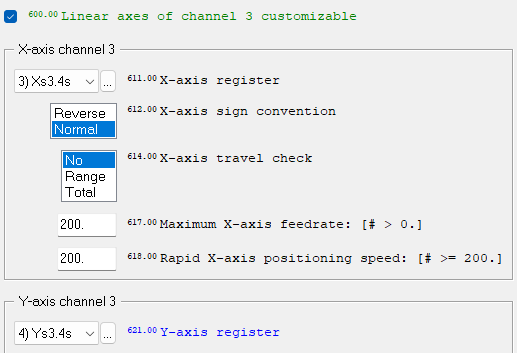

New multi-level trace for added detail during processing: It is now possible to have more detailed extra information issued to the trace window and listing file during processing. These extra details are intended to help develop and debug runtime processing and have 3 levels of detail. Developer of post-processor, Control Emulator or Virtual Machines can also use this feature to include their own debug messages.

The debug level can be adjusted at any time during processing by using the Tools->Preference dialog debug tab and setting the Debug Level drop down list to the desired level as follow:

Level 0: Debug traces are OFF.

Level 1: For user defined extra information.

Level 2: For internal processing extra information.

Level 3: For even more advanced internal processing information.

A higher Debug Level also includes all extra messages of lower level.

Alternatively, the new $DBGLVL macro variable can be used to query the current Debug Level or change it. This can be done by macro or using the debugger variable window.

User implementing their own messages using this mechanism should test the $DBGLVL and issue their message if the value is not zero.

Virtual Machine

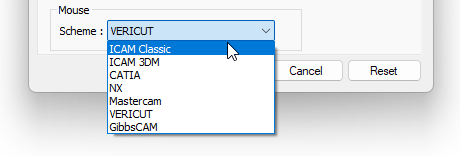

Added new input mouse and keyboard schemes

CGTech VERICUT

GibbsCAM

Enhanced Support for 3DConnexion SpaceMouse Devices. Adding support for the latest devices and improving the responsiveness and smoothness.

Added new feature for using meshes to represent safety zones around component included in collision detection and improve use of collision detection settings. Using safety mesh can greatly improve detection collision performance on complex objects.

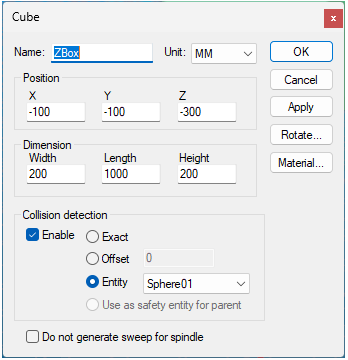

When defining a Virtual Model component in Quest, the component’s property dialog is now showing new settings for collision detection:

Enable: This turns collision detection ON or OFF without losing collision settings when toggled. Pre V25.0 would reset collision settings when turned OFF.

When enabled, the following choices are available:

Exact: Collision detection is done on the component’s mesh directly

Offset: The specified offset is applied on the component’s mesh and used for collision detection.

Entity: Allow selection of another mesh to be used for collision detection. The selected mesh must be a direct child of the component to be valid.

Use as safety entity for parent: Allow setting the parent’s safety mesh from the child entity property dialog.

Component that are used as a safety mesh will be shown with a blueish dot next to them in the Quest Virtual Machine builder navigator tree.

Safety mesh visibility can be toggled using the Safety Zone button on the VM Grid toolbar. Inserting image…

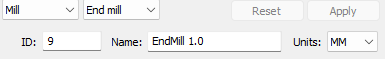

Added support for tool name and corresponding macro function to reference them:

In addition to the tool ID, it is now possible to define a tool name in Virtual Machine tool dialog.

While tool ID must be unique in a simulation, tool name does not have to be.

Tool name can be queried and used in the following macro function: $FMSID, $FMSTOOL and $FMSIDN

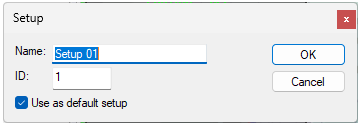

Improved Virtual Machine setups: It is now possible to define a setup name in addition to the setup ID. While setup ID must be unique, Setup name does not have to be.

The default setup is now definable by the user. Default setup is automatically applied at the start of the simulation without the need for a LOAD command or user interaction. It is also possible to not have a default setup.

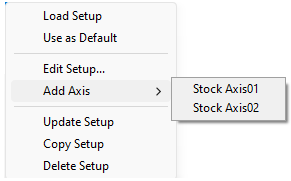

New context menu allows for easier management of setups from the Virtual Machine Simulation Manager window.

CeRun Run-Time

The ICAM Control Emulator interface to 3DEXPERIENCE DELMIA machine simulation has been improved to be able to support large machine cells. Increase number of supported axes in Integration section of the questionnaire from 46 axis to 99.

Support for motions having more than 6 axes moving simultaneously.

Improved flexibility on assigning NC program to specific devices and channels. See detail in the Macro Functions and System Variable section.

Integration Tools

Manufacturing Extractors and the CAM Integration utility have been updated to support the following CAM systems and releases:

3DEXPERIENCE 2015x–2024x

CATIA V5R21, V5-6R2012–2024

Creo1–10

FeatureCAM 2017–2022

Fusion 360

Mastercam 2017–2024, and for SolidWorks 2014–2019

NX12, NX1847–2406

PowerMill 2017–2024

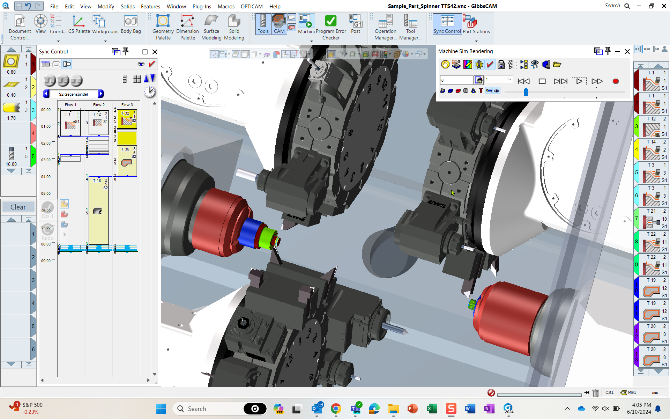

New CAM integration with GibbsCAM, enabling the generation of ICAM CL files and the ability to launch the GENER post-processor from GibbsCAM.

The Creo extractor interface was simplified to provide a better user experience.

Enhancements have been made to the extractor for CL files handling. Automating CL file selection and improving default naming convention.

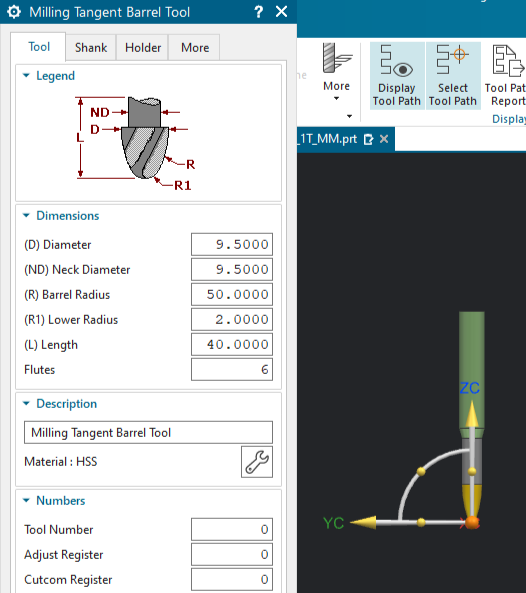

SIEMENS NX: Implemented support for tangent barrel tool.

Macro Functions and System Variables

GENER post-processor:

$FCLINFO function provides a fast look-ahead mechanism for analyzing the CL records.

$FCLINFO([ALL|TOOL|(ID|CLREC,n][[,str],end]).

$CLOOK variable indicate if the processing is currently in a CL look-ahead.

$MTNLPP variable automate enabling motion startup and shutdown macros only for generated motion from path planning, RTA and SmartPATH.

$FOPPATH function will return the sequence of motion generated by path planning, RTA and SmartPATH before they are processed and output.

$FOPPATH((id|AUTO)[,type])

$OPPATHI variable return the ID of the next motion to process or zero if all motions has been processed or there is no list.

$HEAD, $OE.HEAD and $INFO.HEAD can now have the keyword value RIGHT for the mill-Turn third channel.

CERUN:

$MFICNT is a read-only variable providing the number of input MCD program files available from the launch parameters. This is independent of the number of CE kernels. The following variables provide information about those input MCD files:

$MFINAM(1:16): MCD input file path. This variable is read-only.

$MFICHN(1:16): Starting channel number of the given MCD input file. This variable in writable.

$MFIKER(1:16): Kernel id assigned to the given MCD input file. This variable is writable.

$MCEINP(1:16): Used to assign MCD file index to kernel instances. This array is the number of kernel available.

Added a multi-kernel synchronization method. The CERUN processing kernels can now synchronize their speed of processing based on the Virtual Machine channel cycle time. This feature is OFF by default and can be turned ON only in the super kernel “Machine Startup” macro by calling $FCETIMESYNC(). This is only available for merging lathe and composite CE.

The Cycle Event macro has a new $P6 variable that indicates the BORE-BACK bottom clearance plane value.

Added support for the following cycle variables: $CRMODE, $CYCLR{XYZ}, $CYCLRO, $CYDECR, $CYDIR, $CYDPTH, $CYFEDT, $CYFEDV, $CYINCR, $CYMCH, $CYORNT, $CYRATIO, $CYRETN, $CYRIGID and $CYTYPE.

GENER & CERUN

$DBGLVL is a system variable that indicates what is the current level of the multi-level debug tracing. This is tied to the same level selection as in the Debug > Preferences menu. It can also be modified.

Virtual Machine:

$FMSTOOL, $FMSID and $FMSIDN have been extended to support querying tool name as defined in the Virtual Machine tool panel.

PQRs

The following is a partial list of corrections made to V25.0.

CAM-POST

PQR |

Description |

|---|---|

0 06585 |

Fixed potential error caused by calling FLOOK or FINFO from within a subprogram and have it run past the end of the subprogram. [V24.2‑2415] |

0 06577 |

When processing this file after a CIRCLE+GOTO, some intermediate #1002 record would be skipped before the next GOTO. [V24.2‑2414] |

0 06554 |

Fixed an issue with multi-point records under merging environment. [V24‑2406] |

0 06543 |

Gener was generating “Invalid continuous motion modifier word in APT file” error message when processing 2d circular motion with TLON,GOFWD/(CIRCLE/..),ON,(LINE/…) when AUTOPS is programmed on non XY plane circles. [V24.2‑2405] |

0 06541 |

Fixed an issue where GENER “View tape file” button on the main interface would not use the current Windows editor associated to the tape file extension. [V24.2‑2402] |

0 06495 |

Fix issue when reading PowerMill DUCT5 format where strings with carriage returns were not handled correctly causing Gener to generate a Fatal Error. [V24.2-2341] |

0 06601 |

Using ROTABL/…,ROTREF could come into a situation where the rotary axis position internally would be offset by 360 degrees and would then hang the processing. [V24.2-2421] |

Control Emulator

PQR |

Description |

|---|---|

0 06571 |

Fixed an issue processing SIEMENS $P_SDIR variables when referenced with an array element. [V24.2-2411] |

0 06526 |

Fix offset observed in the 3DEXPERIENCE DELMIA NC code display during the playback of the simulation. The line indicator was not showing the right motion being simulated when programs contain some empty blocks. [V24.2-2349] |

Virtual Machine/CAM Integration

PQR |

Description |

|---|---|

0 06599 |

Fix bad normal vector of triangles generated by extruded and revolved profiles. [V24.2‑2419] |

0 06568 |

Fixing the CATIA probing tool extraction. The tool definition for the Ball Stylus Prob tool was outputted as Mill type instead of proper probing. [V24-2411] |

0 06521 |

Fix for 3DEXPERIENCE extractor. Fixture compensation setup was not being extracted properly. [V24.2-2347] |

0 06579 |

Having machinable fixture that has been cut will cause SmartPATH impossible to start if the first positioning motion is from the cut fixture area. [V24-24244] |